Formation of CuCrCoFeNiO high entropy alloy thin films by rapid thermal processing of Cu/CrNiO/FeCo multilayers

AnniWanga, Manuel OlivaRamireza, MariaCaplovicovab,ViliamVretenarb, JuliusBoettchera, MarcusHopfelda, ThomasKupsa, DominikFlocka, PeterSchaafa

Surface and coatings technology, ISSN 0257-8972, 405 (2021), 126563

doi.org/10.1016/j.surfcoat.2020.126563

Abstract

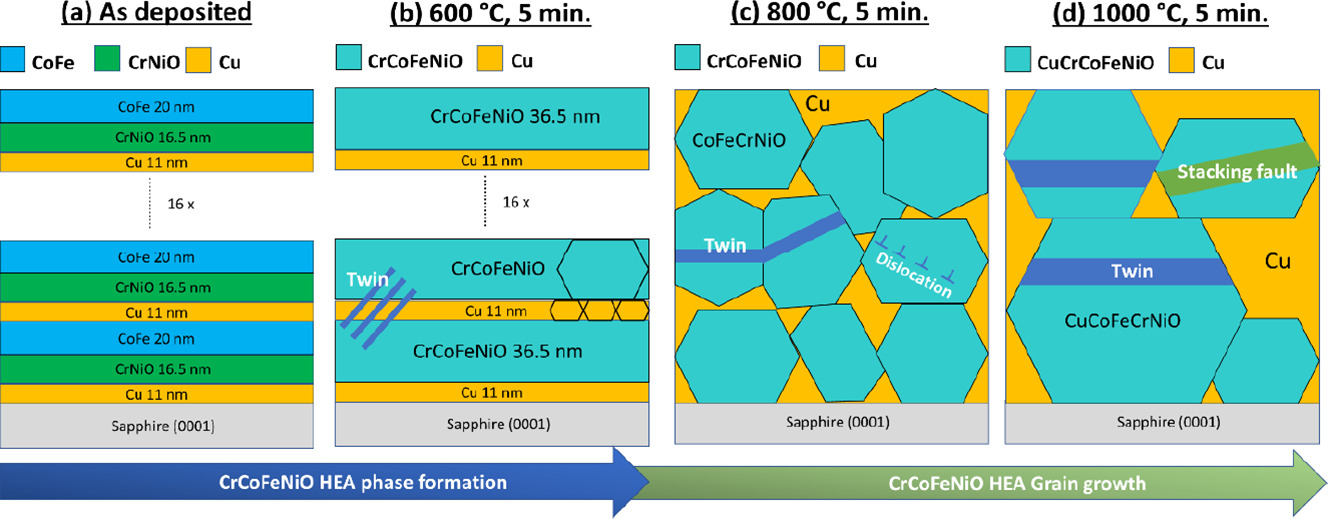

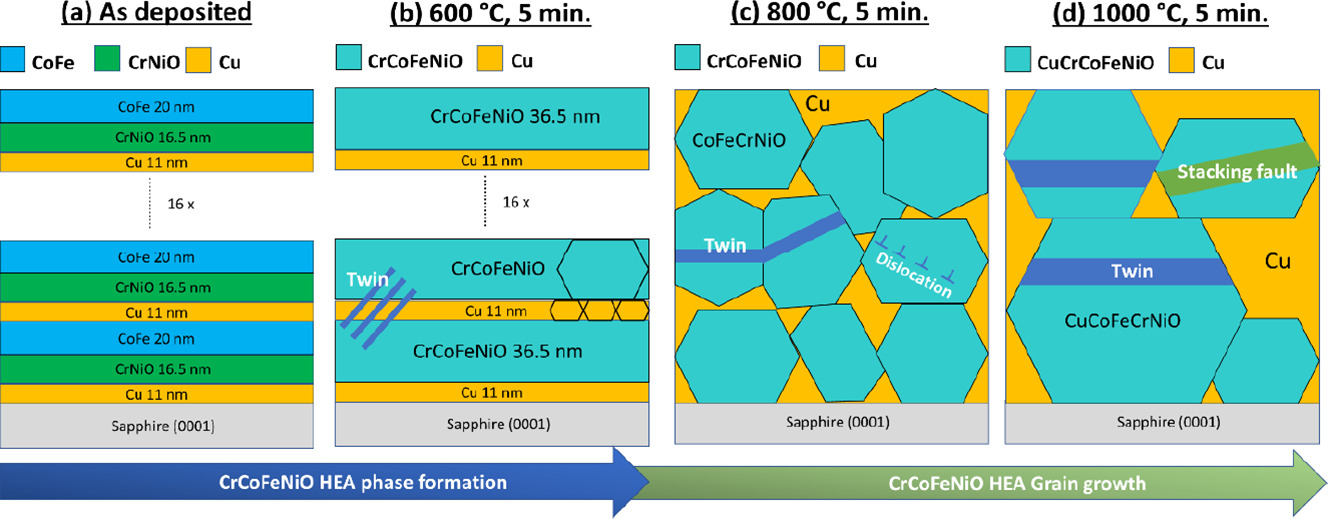

This study presents the synthesis of High Entropy Alloy (HEA) films starting from elemental Cu and binary alloy CoFe and CrNiO multilayers, followed by rapid thermal processing (RTP). By that, the HEA films (HEAFs) were formed by phase formation via short-range and fast diffusion processes. Multilayers with a total thickness of 760 nm consisting of 16 repetitions of a Cu (11 nm)/CrNiO (16.5 nm)/CoFe (20 nm) sequence were annealed at temperatures from 600 °C to 1000 °C for 5 min. The reaction products were then analyzed by means of X-ray diffraction (XRD) and transmission electron microscopy (TEM) combined with electron energy loss spectroscopy (EELS), in order to identify the phase transformations and elemental distributions. A duplex FCC structure containing CrCoFeNiO HEA and pure Cu phase was successfully synthesized at 600 °C and 800 °C by the solid-state reaction. CuCrCoFeNiO HEA formed within in a Cu nanocrystalline matrix. As the annealing temperature increased, the oxygen content in the films decreased, Both HEA and Cu possess significant 〈111〉 preferred orientation. The HEA phase demonstrated a typical microstructure of alloys with intensive nano-twins. Moreover, the grain growth kinetics of the HEA phase was evaluated, and the activation energy was found to be 185(10) kJ/mol. This is comparable to that of conventional stainless steel (~150 kJ/mol) and less than half of the value for CrCoFeNi bulk (434 kJ/mol). A surface energy-driven grain growth mechanism of the HEAFs via multilayer alloy formation is proposed in this study. The mechanical properties, hardness and Young’s modulus, were measured via nanoindentation, and the strengthening mechanism was proposed and compared with current literature.