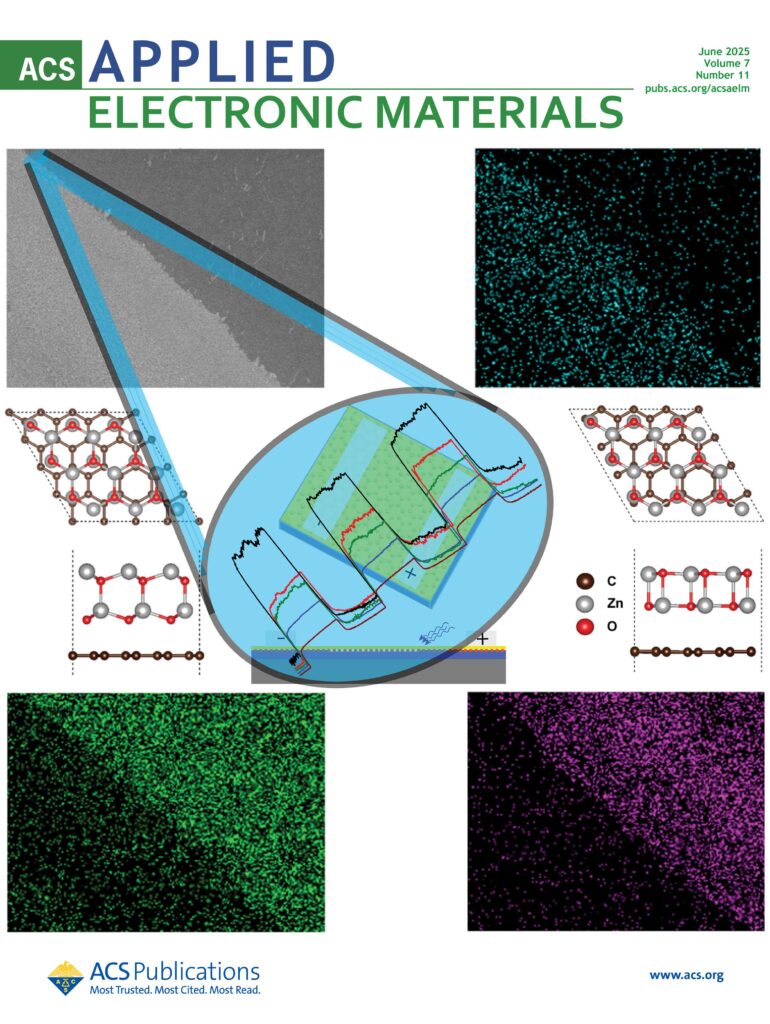

Publikácia Graphene-ZnO Thin-Film Heterostructure-Based Efficient UV Photosensors, na ktorej sme sa autorsky podieľali, bola nedávno umiestnená na titulnú stranu časopisu ACS Applied Electronic Materials . Dr. Ravi K. Biroju, hlavný autor publikácie, vysvetľuje, že daná práca demonštruje prípravu van der Waalsovej heteroštruktúry grafén/ZnO v podobe tenkej vrstvy metódou CVD. Ak skombinujeme priamy polovodičový materiál s veľkou šírkou zakázaného pásma ako ZnO a vodivú vrstvu grafénu, dostaneme platformu s možnosťami jej aplikácie v oblasti fotosenzorov, alebo plynových senzorov. V prípade osvetlenia danej štruktúry dôjde k efektívnej separácii svetlom generovaných elektrón-dierových párov lokálnym elektrickým poľom, čo efektívne potlačí ich rekombináciu a zvýši životnosť nosičov náboja. Výsledkom je k zvýšenie hustoty nosičov náboja. Ďalej to vedie k zníženiu Schottkyho bariéry medzi tenkou vrstvou ZnO a grafénom, čo zlepšuje transport nosičov náboja. Výsledkom je vysoký pomer prúdov osvetlenej a neosvetlenej štruktúry Ilight/Idark , oveľa väčší než pre samotné tenké vrstvy, alebo nanoštruktúry ZnO.