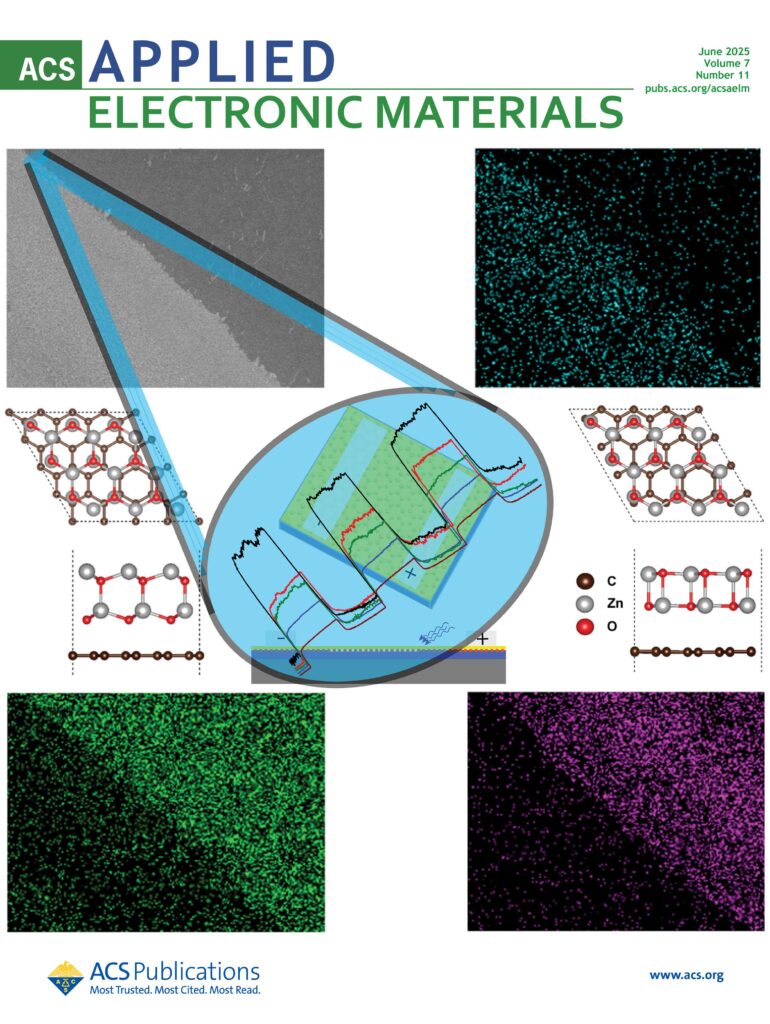

Recently, the Supplementary Cover Art for manuscript: “Graphene-ZnO Thin-Film Heterostructure-Based Efficient UV Photosensors” has been published in the ACS Applied Electronic Materials. Dr Ravi K. Biroju, who is the main author of this article explains, that this work basically demonstrates fabrication of CVD grown graphene/ZnO thin-film van der Waals heterostructures. When we combine a wide direct band gap semiconductor such as ZnO and a highly conductive layer of graphene, we get a unique platform for applications such as photosensors and gas sensors. Under light illumination, the effective separation of photo-generated electron−hole pairs by the local electric field suppresses carrier recombination rates and increases carrier lifetime. This leads to an increased free carrier density. It can reduce the Schottky barrier between graphene and the ZnO thin film, facilitating the transport and collection of photocarriers. As a result, a high Ilight/Idark ratio can be achieved, much higher than for bare ZnO thin films or ZnO nanostructures.